Why Coated Stainless Steel Ductwork Outlasts Traditional Materials in Chemical Processing

Process exhaust ductwork operates in conditions that standard materials weren't designed to handle. Acids at elevated temperatures. Concentrated alkalis. Process gases that corrode from inside, while outdoor conditions attack from outside.

The wrong material choice shows up eventually—premature corrosion at flanges, structural failure under thermal cycling. By the time damage appears externally, you're already scheduling emergency replacements and explaining production downtime.

Coated stainless steel outlasts traditional materials like PVC and FRP by combining the mechanical strength and fire safety of steel with the chemical resistance of fluoropolymer coatings. This hybrid construction allows the system to withstand temperatures up to 300°F, meet the most stringent Class 1 fire codes, and remain immune to UV degradation—all while remaining easy to modify on-site.

The following technical benchmarks illustrate why coated stainless steel delivers the lowest total cost of ownership:

Key Takeaways

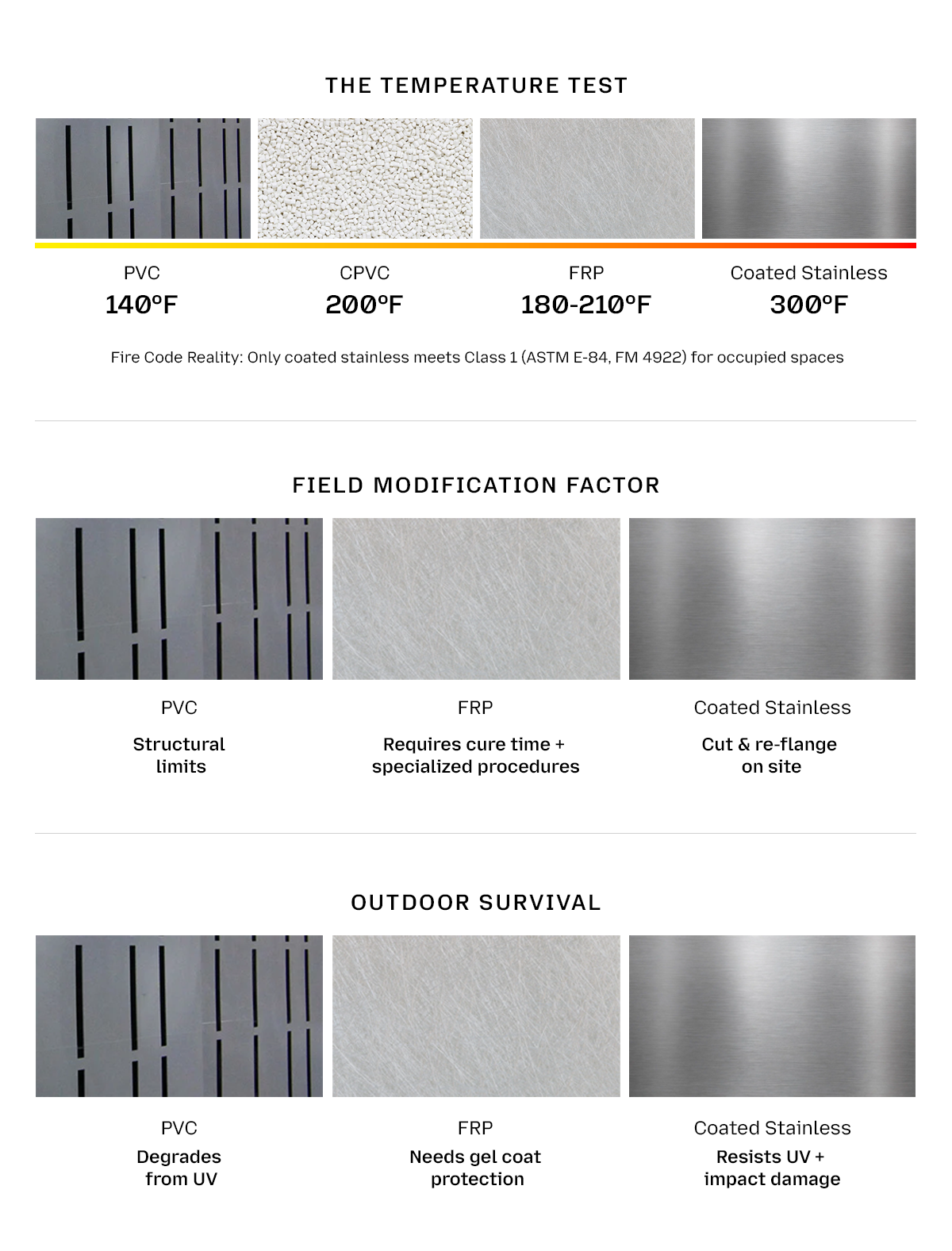

- Temperature limits: PVC: 140°F. CPVC: 200°F. FRP: 180-210°F. Coated stainless: 300°F continuous.

- Fire ratings: Coated stainless meets Class 1 (ASTM E-84, FM 4922)—often the only code-compliant option for occupied spaces.

- Field modifications: Coated stainless cuts and re-flanges on site. FRP needs specialized procedures and cure time.

- Outdoor durability: Coated stainless steel resists UV and impact. PVC degrades from sunlight. FRP performs well with proper gel coats but lacks metal's impact resistance.

- Lifecycle costs: Higher upfront, but maintenance-free operation and extended life make coated stainless the lowest total cost for high-temperature, fire-rated applications.

The Material Selection Problem Nobody Talks About

Many facilities make material decisions based on upfront cost without calculating long-term expenses. However, the lowest bid often leads to the highest total cost of ownership when you factor in replacement frequency, maintenance requirements, and downtime throughout the lifecycle of your materials.

PVC and Thermoplastics: The Temperature Wall

PVC ductwork works remarkably well for specific chemical environments—certain acid concentrations at moderate temperatures with straightforward routing. For smaller projects with limited budgets, thermoplastics offer genuine cost advantages.

Then you hit the limitations.

Temperature kills thermoplastics faster than anything else. Standard PVC ductwork maxes out at 140°F continuous operation. CPVC (chlorinated PVC) extends this to approximately 200°F, but at significantly higher cost than standard PVC. Chemical processing applications frequently exceed these thresholds, especially near heated reactors or distillation equipment.

That said, poor installation, UV, and mechanical abuse can also be dominant failure modes in some settings.

Their structural issues compound the problem. Thermoplastics have lower stiffness than FRP or metal, requiring more frequent support spacing for large diameter runs. Thermal expansion creates another headache—PVC expands significantly more than steel per degree of temperature change, requiring careful management of expansion joints and support systems.

Fiber-reinforced plastics already have a modulus of elasticity an order of magnitude lower than steel; PVC and other unreinforced thermoplastics are still less stiff than FRP, so both FRP and thermoplastics require shorter support spans than steel to control deflection.

UV degradation becomes unavoidable outdoors. An unprotected thermoplastic duct exposed to sunlight experiences UV-driven degradation over time unless you've specified UV-stabilized materials, dark pigments, or external shielding. PVC, CPVC, and other thermoplastics undergo surface oxidation, embrittlement, discoloration, and loss of toughness over time when exposed to sunlight.

Many facilities discover this limitation after installation, not before.

FRP: The Middle Ground Solution

Fiberglass reinforced ductwork occupies the performance zone between thermoplastics and coated metals. When properly engineered with vinyl ester resins matched to your specific chemical exposure, FRP handles acids, alkalis, and organic solvents that destroy other materials.

FRP brings advantages that thermoplastics can't match. Custom fabrication accommodates complex geometries through multi-story facilities. Outdoor installations with UV-resistant gel coats operate for decades. Large diameter runs (48-120 inches) maintain structural integrity with reasonable support spacing.

Temperature performance improves significantly over PVC—FRP systems, with standard vinyl ester resins handling continuous operation at 180-210°F. That covers many chemical processing applications where thermoplastics fail.

But FRP has limitations you need to understand upfront.

Field modifications require specialized procedures. Field modifications require specialized procedures, and that means a trained specialist. For larger duct diameters, the code requires internal bonds, which are challenging on existing systems. Plan your initial design carefully, because changes later create complications.

Fire ratings present challenges in occupied spaces. While FRP can achieve Class I flame ratings with specific resins and additives, many building codes favor materials with inherently superior fire performance—which brings us to coated stainless steel.

Uncoated Stainless Steel: Chemical Resistance Limitations

Many facilities assume 304 or 316 stainless steel provides universal corrosion resistance. It doesn't.

Stainless steel handles mild corrosives reasonably well, but concentrated acids create problems. Hydrofluoric acid attacks stainless steel aggressively. Hydrochloric acid causes pitting and crevice corrosion. Sulfuric acid at elevated temperatures degrades even 316 stainless steel over time.

The real issue with uncoated stainless is that corrosion often initiates at welds, gaskets, and connection points—exactly where you can't easily inspect or repair without system shutdown. By the time external corrosion appears, internal damage has progressed significantly.

Why Coated Stainless Steel Wins Long-Term

Performance & Compliance Advantages

Coated stainless steel systems combine the structural strength of metal with the chemical resistance of fluoropolymer coatings, allowing them to outperform plastics and FRP in high-risk chemical processing environments.

Temperature capability

Coated stainless steel handles 300°F continuous operation, covering high-temperature reactor exhaust, thermal oxidizer connections, and heated scrubber discharge. By comparison, FRP typically tops out at 180–210°F, and PVC fails well below that threshold.

Fire safety and code compliance

Coated stainless meets Class 1 fire requirements under ASTM E-84 and FM 4922. For occupied spaces or facilities governed by stringent fire codes, this often makes coated stainless steel the only code-compliant ductwork option, eliminating the need for internal sprinklers and reducing long-term compliance risk.

Chemical resistance without absorption

The fluoropolymer lining resists acids, alkalis, and solvents without absorbing chemicals into the duct wall—avoiding degradation over time and simplifying end-of-life disposal compared to some FRP systems.

Installation, Modifications & Lifecycle Cost

Beyond performance, coated stainless steel excels in the realities of operating industrial facilities.

Field modifications without downtime

Unlike FRP, coated stainless steel can be cut and re-flanged on site with no cure time or specialized crews. Adding a branch connection years after installation is a mechanical task—not a resin-handling project.

Outdoor durability and impact resistance

Coated stainless does not degrade under UV exposure, resists impact damage, and maintains structural integrity through decades of outdoor service. This eliminates the inspection, recoating, and protection measures required for plastics and FRP in harsh environments.

Lower total cost of ownership

While coated stainless steel carries a higher upfront cost, its maintenance-free operation, extended service life, and reduced downtime risk often make it the lowest total cost option when temperature limits, fire codes, and uptime matter. In lower-temperature, non-fire-rated applications, FRP may still be the most economical choice—but those cases should be evaluated deliberately.

Ductwork Material Showdown - Chemical Processing

The Bottom Line Coated stainless steel has a higher upfront cost, is virtually maintenance-free, has extended service life, and is the lowest total cost of ownership when temperature + fire ratings matter.

When Coated Stainless Steel Makes Sense

Not every application requires coated stainless steel's premium performance. But several scenarios make it the optimal choice:

- Fire code requirements. Occupied spaces requiring Class 1 fire ratings eliminate most FRP and all thermoplastic options immediately. Some FRP and plastic duct products are specifically engineered and tested to meet ASTM E84 Class 1 and even FM 4922 and UL 181.

- Temperature extremes. Chemical processes operating above 210°F (the typical limit for standard FRP vinyl ester resins) need coated stainless steel's temperature capacity.

- Critical uptime operations. Facilities where ductwork failure creates six-figure downtime costs cannot afford the maintenance frequency of lesser materials.

- Outdoor installations in harsh climates. UV exposure, temperature cycling, and weather impact degrade other materials faster than coated stainless steel.

- Hazardous waste concerns. Coated stainless steel doesn't absorb chemicals into the wall structure, so end-of-life disposal avoids hazardous waste classification that FRP sometimes triggers.

Viron's SSTeelcoat: Engineering Coated Stainless Steel for Chemical Processing

SSTeelcoat is Viron’s coated stainless steel ductwork system designed for chemical processing environments where temperature limits, fire codes, and corrosion resistance must all be satisfied simultaneously.

It delivers long-term reliability by combining stainless steel’s structural strength with a chemically inert fluoropolymer lining—without sacrificing installability or compliance.

What SSTeelcoat Delivers

- Continuous operation up to 300°F

- Class 1 fire performance meeting FM 4922 requirements

- Resistance to aggressive acids, alkalis, and solvents

- Field-modifiable construction without cure time or hazardous resins

Engineering & Construction Details

- Base material: 304 or 316 stainless steel

- Internal lining: Halar® (ECTFE) fluoropolymer applied via electrostatic powder coating

- Sizes: Custom fabrication from 4 inches to 120+ inches in diameter

- Connections: Flanged and banded Van Stone joints—no welding or resin wrapping required

- Certification: FM-labeled, low flame spread and smoke development

Proven in Long-Term Service

SSTeelcoat installations have operated for 15+ years in chemical processing, wastewater treatment, and metal finishing facilities without the maintenance, premature failures, or compliance concerns associated with traditional duct materials.

When exhaust chemistry is aggressive, temperatures are elevated, and downtime is unacceptable, SSTeelcoat provides the durability and operational flexibility that PVC and FRP cannot.

Ready to evaluate whether coated stainless steel makes sense for your chemical processing facility? Contact Viron's engineering team for a material analysis specific to your exhaust chemistry and operating conditions.

FAQs

How does coated stainless steel ductwork compare to FRP for chemical resistance?

Both handle aggressive acids, alkalis, and solvents effectively when properly selected. FRP uses vinyl ester resins matched to specific chemicals. Coated stainless steel uses Halar® (ECTFE) over 304/316 stainless steel. The difference: coated stainless adds 300°F temperature capacity (vs. FRP's 180-210°F), Class 1 fire ratings, easier field modifications, and superior impact resistance. Choose based on your temperature requirements, fire codes, and modification needs.

What makes coated stainless steel worth the higher upfront cost compared to PVC or FRP?

Total cost extends beyond purchase price. Coated stainless operates maintenance-free, handles 300°F (vs. 140°F PVC, 180-210°F FRP), meets Class 1 fire ratings, and allows field modifications without cure times. It doesn't absorb chemicals—avoiding hazardous waste classification. For facilities where downtime costs are significant, fire codes require Class 1, or temperatures exceed 210°F, coated stainless delivers lowest total cost of ownership.

Can coated stainless steel ductwork be installed outdoors in harsh climates?

Yes. Coated stainless excels outdoors—no UV degradation, withstands temperature cycling, resists impact damage. Unlike PVC (needs UV protection) and FRP (needs gel coats and inspection), coated stainless handles decades of outdoor exposure with minimal maintenance. Wastewater treatment and metal finishing facilities commonly operate systems outdoors for 15+ years.